CATL’s Sodium-Ion Batteries Now Entering Passenger Vehicles

CATL has officially begun deploying its third-generation sodium-ion batteries in passenger vehicles, marking a major milestone in commercializing this alternative battery technology. The company’s Naxtra-branded sodium-ion batteries are already undergoing winter testing in models from Changan Automobile’s Oshan sub-brand, with GAC Aion and JAC vehicles set to follow. Mass production is expected to begin in Q2 2026, with the first passenger vehicle equipped with these batteries arriving as early as July.

Background: CATL’s Sodium-Ion Journey

CATL unveiled its first-generation sodium-ion battery in July 2021 as lithium carbonate prices surged, positioning the technology as a sustainable alternative to traditional lithium-ion batteries. The company formally launched its Naxtra brand in April 2025 at its Tech Day event, signaling a strategic commitment to scaling sodium-ion technology across multiple market segments. This progression reflects CATL’s broader strategy to diversify its battery portfolio and reduce dependence on lithium-based chemistry.

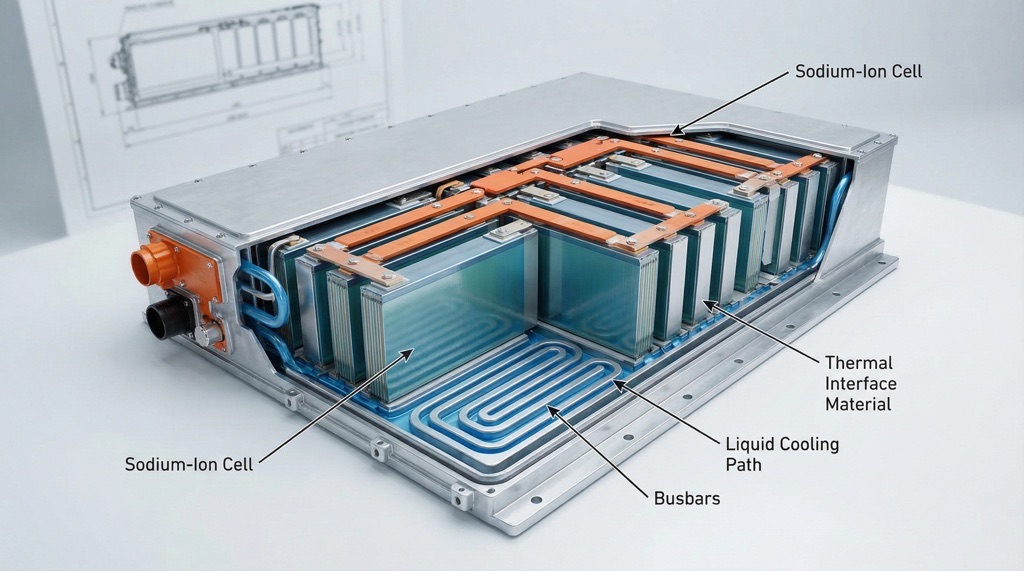

The company has already demonstrated the viability of sodium-ion technology in commercial vehicles. CATL’s Tectrans II series, introduced in January 2026, includes a 45 kWh sodium-ion battery pack designed for light commercial vehicles—the industry’s first of its kind. These batteries completed winter testing in light trucks and mid-size vans from JAC Corp, proving their durability in extreme conditions.

Key Specifications

| Specification | Details |

|---|---|

| Energy Density (Naxtra) | Up to 175 Wh/kg (matches LFP batteries) |

| Charging at -30°C | Fully functional |

| Capacity Retention at -40°C | 90% of usable capacity |

| Temperature Rise (5 °C charging) | No more than 5°C |

| Long-Range Pack Option | 253 kWh (up to 800 km range) |

| Battery-Swap Pack Variants | 42 kWh, 56 kWh, 81 kWh |

| Commercial Vehicle Pack | 45 kWh (Tectrans II series) |

| Safety Certification | Meets China’s GB 38031-2025 standard |

Why Sodium-Ion Now? Cold Performance and Cost Advantages

CATL’s sodium-ion batteries solve a critical problem for EV adoption in cold climates. Traditional lithium-ion batteries lose significant capacity in freezing temperatures, requiring energy-intensive thermal management systems. CATL’s Naxtra batteries retain 90% of their usable capacity at -40°C and can charge at temperatures as low as -30°C without degradation. This eliminates the need for additional cooling systems, reducing overall vehicle complexity and cost.

The cost advantage is equally significant. Sodium-ion batteries use less expensive, more abundant materials compared to lithium-ion chemistry, directly lowering production costs. CATL chief technology officer Gao Huan emphasized that sodium batteries excel at high-power discharge, with temperature rise limited to just 5°C during 5 °C charging rates, further reducing thermal management overhead.

CATL’s third-generation sodium-ion batteries have already passed China’s new national battery safety standard (GB 38031-2025), addressing regulatory requirements for passenger vehicle deployment. The company plans to achieve energy density parity with lithium iron phosphate (LFP) batteries within three years, though current Naxtra batteries already match LFP’s 175 Wh/kg performance.

Market Deployment Strategy: Four Sectors in 2026

CATL’s 2026 strategy targets four major market segments for sodium-ion battery deployment: battery-swapping systems, passenger vehicles, commercial vehicles, and energy storage. The passenger vehicle segment focuses on compact to mid-range city cars and daily drivers—segments where lower cost and cold-weather reliability provide the strongest competitive advantage.

The first passenger vehicle to receive Naxtra batteries will be a GAC Aion model in Q2 2026. Changan Automobile’s Oshan sub-brand is already conducting winter testing with sodium-ion-equipped vehicles. JAC vehicles have completed winter testing and are positioned for production deployment. This multi-manufacturer approach signals broad industry acceptance and reduces CATL’s reliance on any single OEM partner.

CATL expects to begin mass-producing sodium-ion batteries in July 2026, with production capacity expanding as demand grows across these four sectors. The company has also developed battery-swap variants in 42 kWh, 56 kWh, and 81 kWh configurations, positioning sodium-ion technology as a core component of China’s expanding battery-swap infrastructure.

Competitive Positioning: Sodium-Ion vs. Lithium-Ion and LFP

Sodium-ion batteries occupy a distinct market position. They are not positioned as direct replacements for premium lithium-ion batteries used in high-performance EVs, but rather as cost-effective alternatives for mass-market vehicles where cold-weather performance and affordability matter more than maximum energy density. This complementary positioning allows CATL to serve diverse customer segments without cannibalizing its existing lithium-ion business.

Compared to LFP batteries, sodium-ion currently offers comparable energy density (175 Wh/kg) but superior cold-weather performance and lower material costs. LFP batteries remain the standard for mid-range EVs globally, but sodium-ion’s advantages in extreme cold environments make it particularly attractive for markets in northern China, Russia, and other cold-climate regions.

Unanswered Questions and Timeline Clarity

While CATL has confirmed Q2 2026 deployment, some ambiguity remains. Recent reports indicate sodium-ion batteries are already installed in test vehicles undergoing winter validation, suggesting production timelines may accelerate beyond initial Q2 projections. However, the distinction between pilot production and true mass production remains unclear—early GAC Aion models may launch in limited volumes before ramping to scale.

Pricing details have not been disclosed, though cost advantages over lithium-ion are expected to be substantial. CATL has not specified which exact GAC Aion variant will receive sodium-ion batteries first, or whether multiple models will launch simultaneously. The company’s third-generation sodium-ion battery development roadmap beyond 2026 also remains undisclosed.

Verdict: A Practical Solution for Mass-Market EVs

CATL’s sodium-ion batteries represent a pragmatic engineering solution rather than a revolutionary breakthrough. By matching LFP energy density while delivering superior cold-weather performance and lower costs, these batteries address real pain points in mass-market EV adoption—particularly in cold climates and price-sensitive segments. The Q2 2026 deployment timeline is credible based on completed winter testing and regulatory certification. This technology is ideal for buyers prioritizing affordability and reliability over maximum range, and for markets where winter performance directly impacts EV adoption rates. For investors and industry observers, CATL’s execution on sodium-ion deployment will signal whether alternative battery chemistries can achieve meaningful market share, or whether lithium-ion dominance will persist despite higher costs.