A new liquid-solid-state lithium battery breakthrough retains over 85% of its capacity at -34°C, addressing a major limitation for electric vehicles in cold regions where traditional batteries lose significant performance. This hybrid design combines liquid and solid electrolytes to maintain high energy output in extreme cold, potentially enabling reliable EV operation in harsh winters without range degradation. EV owners in northern climates stand to benefit most, as this could eliminate the 20-50% range loss common in sub-zero temperatures.

Background

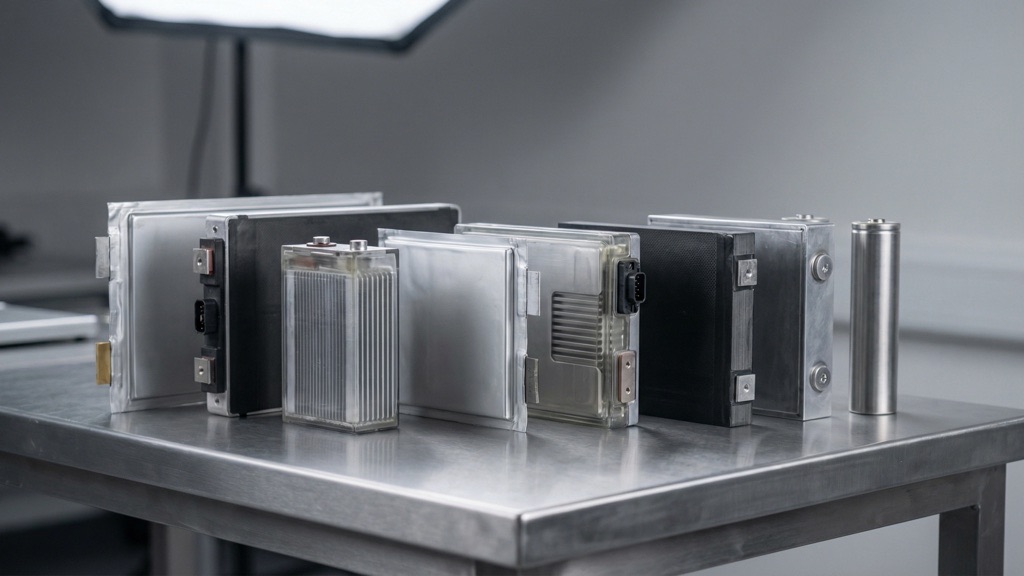

The breakthrough comes from researchers in China, detailed in a February 11, 2026, report, focusing on hybrid liquid-solid-state batteries that bridge the gap between current lithium-ion tech and full solid-state systems. China leads in battery innovation amid its dominance in EV production, with companies like FAW, SAIC, and Dongfeng pushing semi-solid-state and solid-state prototypes. This aligns with global efforts: South Korean KAIST researchers enhanced solid electrolytes with divalent anions for 2-4x better ion mobility using low-cost materials like zirconium. Meanwhile, ProLogium unveiled its Superfluidized All-Inorganic Solid-State Lithium Ceramic Battery at CES 2026, and U.S. firm Factorial Energy partners with Karma for quasi-solid-state integration in the 2027 Kaveya supercar.

China’s battery sector, producing over 70% of global supply, accelerates due to government support and intense competition. FAW’s recent installation of a semi-solid-state pack with 500 Wh/kg density and 1,000 km CLTC range exemplifies this momentum.

Key Specifications

| Parameter | Details |

|---|---|

| Capacity Retention | Over 85% at -34°C |

| Battery Type | Liquid-solid-state lithium |

| Target Application | Cold-region EV packs |

| Related Tech (KAIST) | 1.78 mS/cm conductivity (oxygen-doped), 1.01 mS/cm (sulfur-doped) at room temp |

| FAW Semi-Solid Example | 500+ Wh/kg cell, 142 kWh pack, 1,000+ km CLTC range |

Cold-Weather Performance Analysis

The liquid-solid-state design excels where pure solid-state batteries struggle: low temperatures slow lithium-ion movement in solids, but the hybrid retains fluidity for 85% capacity at -34°C. This outperforms standard lithium-ion batteries, which can drop to 50% capacity or less in similar conditions. For EVs in Canada, Russia, or northern Europe, this means practical usability without preconditioning or reduced payloads.

EV Charge & Range Calculator

https://www.bike-ev.com/calculator/

It helps estimate:

- How far an EV can travel on a given battery size

- How charging to 80% vs 100% impacts usable range

- Why even a 20% energy-density improvement can significantly change daily usability

This puts LMFP’s laboratory results into a real-world context.

Safety and Scalability

Hybrid approaches like this reduce fire risks compared to liquid-only electrolytes while avoiding full solid-state manufacturing hurdles. KAIST’s framework regulation with oxygen/sulfur doping achieves practical conductivity (>1 mS/cm) using cheap zirconium halides, sidestepping costly metals. However, commercialization timelines remain unclear—most projects target 2027-2030 production.

Manufacturing Readiness

Factorial’s FEST quasi-solid tech fits existing lines, aiding quick scaling. ProLogium’s CES 2026 demo highlights thinner, separator-free designs for compact power banks and EVs. China’s FAW claims an ‘industry first’ vehicle install, signaling pilot production.

Comparison with Competitors

| Technology | Key Metric | Source |

|---|---|---|

| Liquid-Solid-State (China) | 85% at -34°C | |

| KAIST Solid Electrolyte | 1.78 mS/cm conductivity | |

| FAW Semi-Solid | 500 Wh/kg, 1000 km range | |

| Factorial FEST (Karma) | 745+ miles in EQS test | |

| ProLogium Ceramic | Ultraslim, 5-min charge claim |

Verdict

This 85% capacity retention at -34°C positions liquid-solid-state batteries as a pragmatic near-term solution for cold-climate EVs, outperforming pure lithium-ion without full solid-state delays. Ideal for fleet operators and consumers in frigid regions, it bridges to higher-density solid-state by 2030. Unanswered: exact energy density, cycle life, and mass-production cost—details not yet confirmed. Watch for vehicle integrations from Chinese OEMs.