A Practical Middle Ground Between LFP and NMC for Mass-Market EVs

UK battery materials developer Integrals Power has reached an important milestone for lithium-manganese-iron-phosphate (LMFP) chemistry. Independent testing shows its LMFP cells can complete 1,500 charge–discharge cycles while retaining more than 80% of their original capacity, a significant improvement over earlier 1,000-cycle results.

The testing was carried out by QinetiQ, adding third-party validation to claims that LMFP could offer electric-vehicle manufacturers a compelling alternative to both traditional LFP and nickel-rich NMC batteries.

Who Is Integrals Power — and Why This Matters

Founded by Behnam Hormozi, Integrals Power focuses on next-generation cathode active materials designed specifically for scalable lithium-ion battery production. The company operates a pilot facility capable of producing up to 20 tonnes per year, using raw materials sourced from Europe and North America.

Its proprietary LMFP formulation contains around 80% manganese, delivers a specific capacity of approximately 150 mAh/g, and operates at a higher 4.1-volt working voltage. That combination allows LMFP to close much of the energy-density gap with NMC while preserving the safety, longevity, and cost advantages associated with LFP.

Independent Test Results: What the Data Shows

QinetiQ evaluated pouch cells built with:

- Integrals Power LMFP cathode material

- standard graphite anodes

- liquid electrolyte

- areal loading of 2 mAh/cm²

Key durability result

After 1,500 cycles at a 1 °C rate, the cells retained over 80% of their original capacity.

This level of durability comfortably meets the expectations for long-lived EV battery packs, particularly in mass-market and fleet applications.

High-rate performance

- 2C discharge: ~99% capacity retention

- 5C discharge: ~92% capacity retention

- 10C discharge: ~60% retention (an extreme use case well beyond normal EV operation)

These results suggest LMFP can handle real-world driving and charging demands without the rapid degradation traditionally associated with high-manganese chemistries.

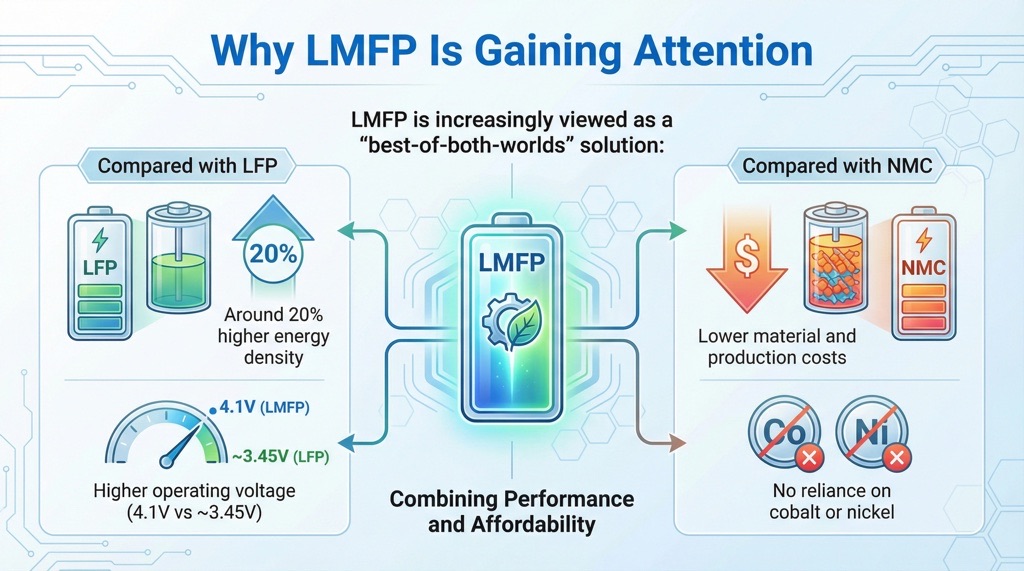

Why LMFP Is Gaining Attention

LMFP is increasingly viewed as a “best-of-both-worlds” solution:

Compared with LFP

- Around 20% higher energy density

- Higher operating voltage (4.1V vs ~3.45V)

Compared with NMC

- Lower material and production costs

- No reliance on cobalt or nickel

- Reduced exposure to supply-chain and ESG risks

For automakers focused on affordability, durability, and secure sourcing, LMFP offers a realistic path to longer range without the cost penalties of nickel-rich chemistries.

What Does 1,500 Cycles Mean in Real Life?

Cycle-life figures are impressive on paper, but drivers ultimately care about kilometers on the road.

A battery that retains more than 80% capacity after 1,500 cycles can translate into hundreds of thousands of kilometers of usable driving range, depending on battery size, charging habits, and vehicle efficiency.

To see how battery capacity and charging levels affect real-world driving distance, you can use this practical tool:

👉 EV Charge & Range Calculator

https://www.bike-ev.com/calculator/

It helps estimate:

- How far an EV can travel on a given battery size

- How charging to 80% vs 100% impacts usable range

- Why even a 20% energy-density improvement can significantly change daily usability

This puts LMFP’s laboratory results into a real-world context.

Safety, Materials, and Scalability

Like LFP, LMFP offers strong thermal stability and a low risk of thermal runaway. Integrals Power states that its patented process mitigates the traditional drawbacks of manganese-rich cathodes, such as rising internal resistance over time.

The company also reports that a second-generation LMFP material is already in development, promising around 30% lower internal resistance, which could further improve fast-charging performance.

While full commercial production timelines have not yet been disclosed, samples have already been supplied to global battery manufacturers and OEMs for evaluation.

LMFP vs LFP vs NMC

| Chemistry | Energy Density | Cost | Critical Minerals | Typical Cycle Life |

|---|---|---|---|---|

| LMFP (Integrals Power) | ~20% higher than LFP | Lower than NMC | No Co / Ni | >80% after 1,500 cycles |

| LFP | Baseline | Low | Low | ~80% after ~2,000 cycles* |

| NMC | +40–50% | High | High (Co, Ni) | ~80% after ~1,000 cycles |

*Depends on cell design and operating conditions

Verdict

Integrals Power’s LMFP breakthrough strengthens the case for a new mainstream EV battery chemistry. It delivers higher energy density than LFP, avoids the cost and supply risks of NMC, and demonstrates durability suitable for long-life electric vehicles.

For automakers building affordable EVs, commercial fleets, and long-warranty platforms, LMFP could become a key enabler. What remains to be seen are pack-level results and large-scale production timelines, but the direction is clear.

LMFP is no longer a lab concept — it is rapidly becoming a viable option for the next generation of electric vehicles.