QuantumScape opened its Eagle Line pilot production facility in San Jose on February 4, 2026, producing QSE-5 solid-state battery cells with 844 Wh/L energy density and 10-80% charging in under 15 minutes. This milestone proves scalable manufacturing of lithium-metal anode batteries via the Cobra process, enabling partners like Volkswagen to test cells that retain 95% capacity after 1,000 cycles. EV buyers stand to gain 25% more range—up to 500 km—without larger packs, addressing key adoption barriers as production data refines costs currently at $400-800/kWh.

Company Background and Market Position

QuantumScape Corporation, founded in 2010 in California, develops solid-state lithium-metal batteries to outperform liquid lithium-ion cells in energy density, charging speed, and safety. Backed by Volkswagen since 2018, the company went public in 2020 via SPAC and has hit all 2025 milestones, including Cobra process integration for QSE-5 production. Its licensing model positions it as a technology provider rather than sole manufacturer, targeting gigawatt-hour scale via blueprints shared with OEMs.

The solid-state battery market, projected to grow amid EV demand, sees QuantumScape leading with real pilot output. Unlike rivals still in labs, Eagle Line ships cells to partners like Volkswagen and Ducati, collecting data for improvements while demonstrating automation for quality control.

Key Specifications

| Specification | Details |

|---|---|

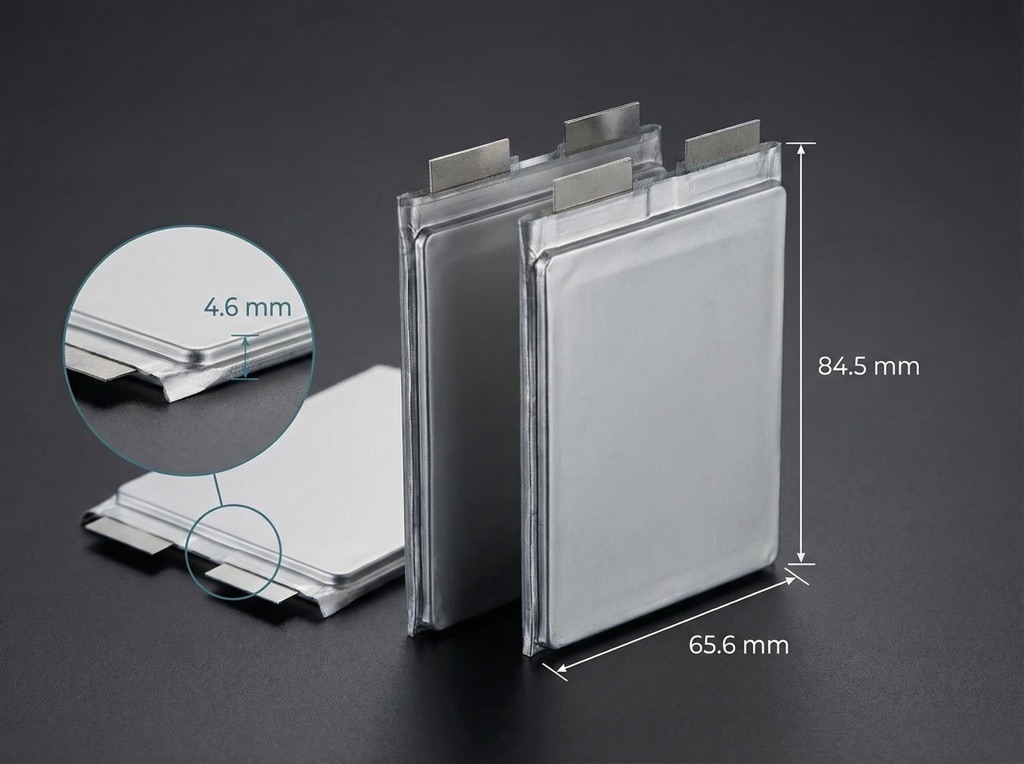

| Cell Model | QSE-5 |

| Energy Density | 844 Wh/L (301 Wh/kg) |

| Charging (10-80%) | <15 minutes |

| Capacity Retention | 95% after 1,000 cycles |

| Expected Lifetime | >483,000 km (300,000 miles) |

| Anode | Lithium-metal |

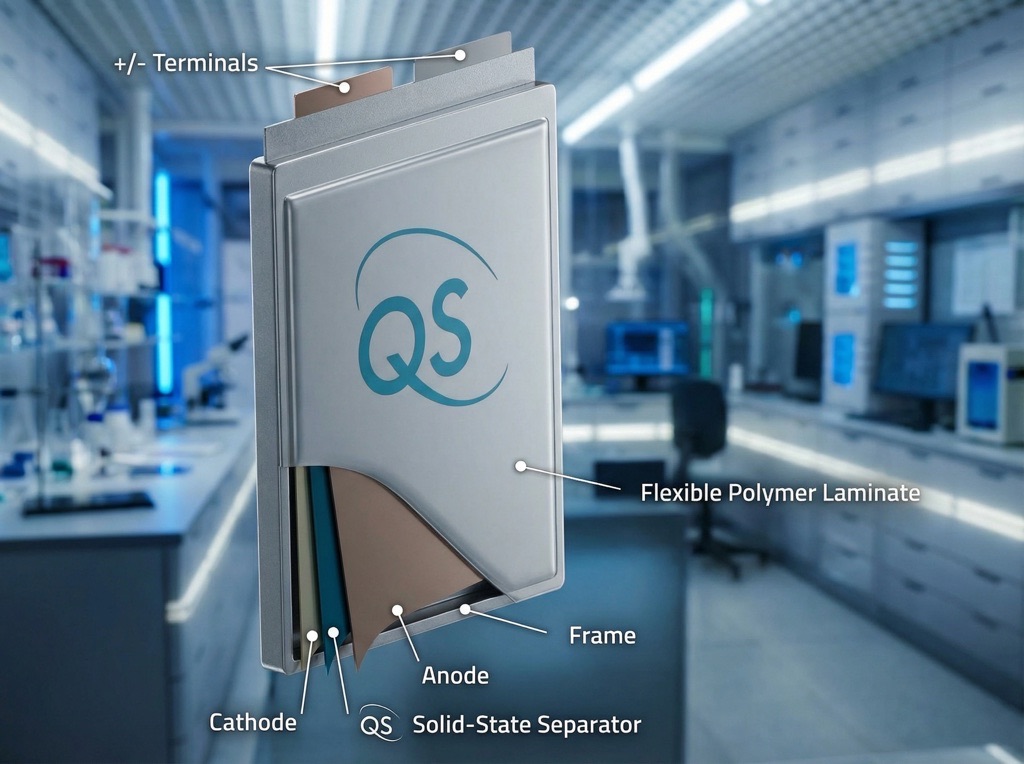

| Separator | Proprietary ceramic (Cobra process) |

| Current Cost Estimate | $400-800/kWh (early production) |

| Production Line | Eagle Line, San Jose (pilot, highly automated) |

Production Milestone: Eagle Line and Cobra Process

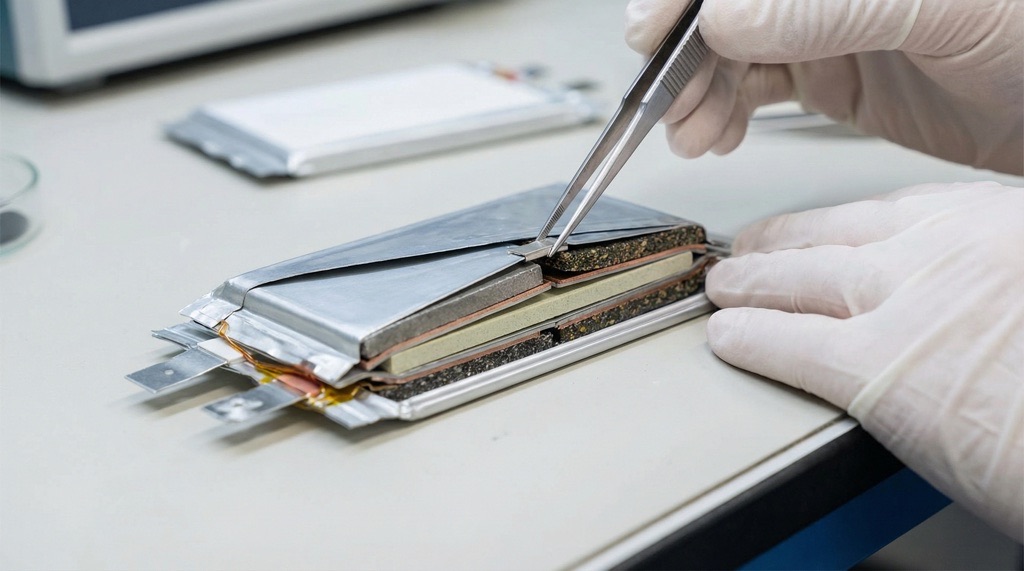

The Eagle Line, inaugurated February 4, 2026, with OEMs, partners, and officials present, uses the Cobra process—a scalable method for ceramic separators that replace flammable liquids and graphite anodes. This enables higher energy storage in the same volume, doubling some current benchmarks, and supports fast charging without dendrite issues plaguing lithium-metal tech. Automation ensures precision, serving as a blueprint for licensees to build GWh-scale factories.

Cells retain high performance over 300,000+ miles, with safety from non-flammable solids handling higher temperatures. CEO Siva Sivaram called it a “Kitty Hawk moment,” shifting QuantumScape to a customer-focused product company. COO Luca Fasoli noted rapid scale-up in output and quality post-Cobra deployment.

Performance and Safety Advantages

QSE-5 cells offer 844 Wh/L volumetric density, translating to 500 km range in a 400 km pack without added weight. Sub-15-minute charging matches gas refueling, while 95% retention after 1,000 cycles exceeds typical lithium-ion degradation. Ceramic separators reduce fire risk, critical for EVs.

Unanswered questions remain: exact ramp-up timelines, cost reduction path to compete with $100/kWh lithium-ion, and real-world integration data from partners. Ducati testing hints at motorcycle applications, but automotive validation is key.

Path to Commercialization and Challenges

QuantumScape ships QSE-5 samples for integration, using Eagle data to iterate. Licensing accelerates adoption, but high early costs ($400-800/kWh) must drop via scale. The line doubles as a lab for next-gen tweaks, vital as competitors like Solid Power or SES lag in pilot output.

Comparison with Competitors

| Aspect | QuantumScape QSE-5 | Solid Power (SP1) | SES AI |

|---|---|---|---|

| Energy Density | 844 Wh/L | 390 Wh/kg (target)[web knowledge] | 400 Wh/kg (lab)[web knowledge] |

| Charging | <15 min 10-80% | ~20 min (projected) | Not specified |

| Production Status | Pilot line operational | Prototype samples | Lab prototypes |

| Partners | VW, Ducati | BMW, Ford | Hyundai, GM |

QuantumScape leads with live pilot production and superior density; Solid Power focuses on sulfide electrolytes with BMW backing, while SES targets hybrid designs but trails in scale.

Verdict

QuantumScape’s Eagle Line launch cements its frontrunner status for solid-state EVs, delivering verifiable specs that tackle range and charging pain points for OEMs like Volkswagen. Ideal for automakers seeking 500+ km range and 15-minute fills, but success hinges on cost cuts and partner integrations by 2028—watch for QSE-5 vehicle tests to confirm real-world gains over incumbents like CATL’s 255 Wh/kg packs.